Briefing: Delivering safely - how communication prevents accidents

Deliveries and collections are essential to business, but can be some of the most dangerous activities you have to deal with. Hazards may include manual handling injuries when loads are moved by hand, health and fire risks if hazardous loads are spilled, and risks from using cranes or other lifting equipment such as lorry loaders. This briefing deals primarily with the main workplace hazards - those to do with the vehicles involved. It is often the drivers of those vehicles who are the victims.

What's the problem?

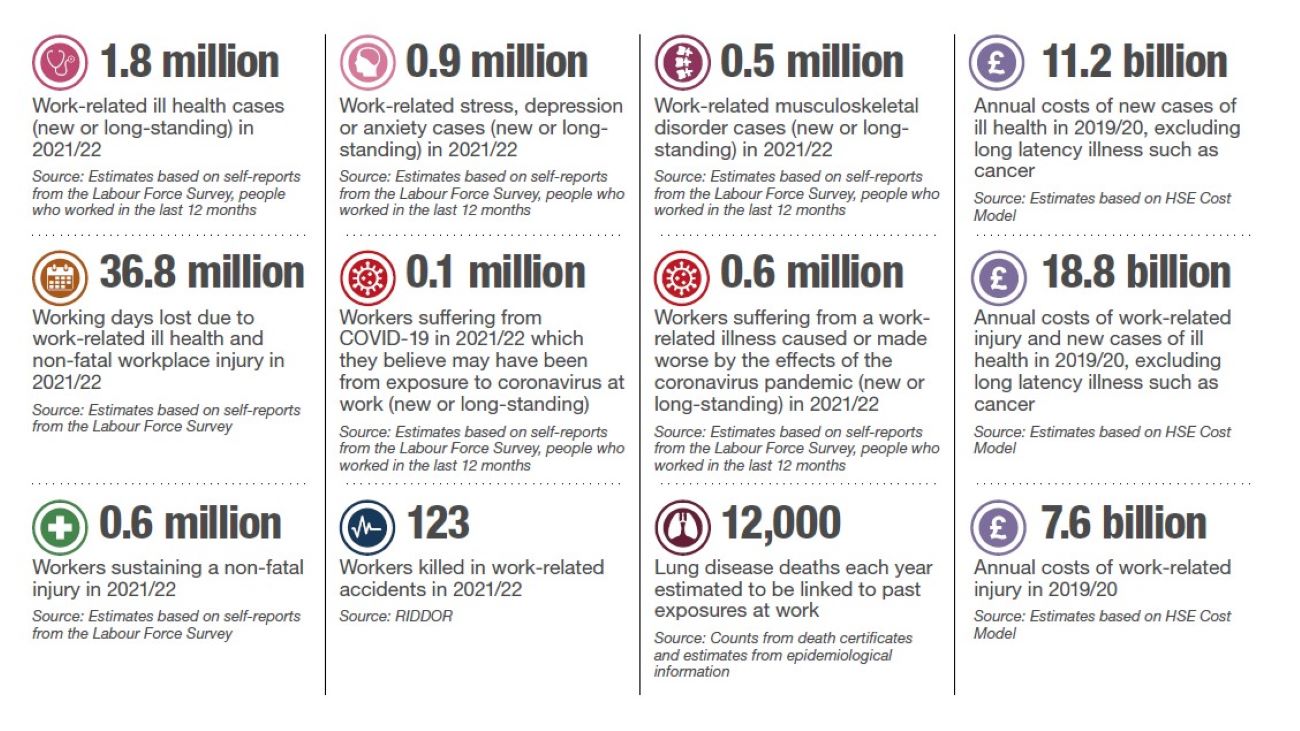

Every year, about 70 people are killed and 2000 seriously injured in accidents involving vehicles in and around workplaces. A significant number of these occur during deliveries and collections. Unless effective precautions are taken, people are at risk from:

- Pedestrians being hit by moving vehicles.

- People falling from vehicles.

- Vehicles turning over.

- People being hit by objects falling from vehicles.

Key responsibilities

Accidents could often have been prevented if duty holders had cooperated with one another.

The three key duty holders are:

- The supplier sending the goods.

- The carrier - the haulier or other company carrying the goods.

- The recipient - the person receiving the goods.

According to the HSE, a common factor in delivery accidents is the lack of any agreement between supplier, carrier and recipient about ‘who is responsible for what’ in terms of safety. In most work situations the safety of an employee is primarily the responsibility of his or her employer, but in order to deliver or collect goods employees have to visit premises controlled by others. The safety of everyone at these premises, including people visiting the site, is in the hands of the person in charge of the site (the recipient or supplier) as they should control what takes place on site.

Irresponsible employers may use this overlap in responsibilities as an excuse for not doing more to protect those involved in deliveries. This overlap can cause dangerous misunderstandings unless all parties exchange information about the main risks involved, and agree who will do what to control risks.

Duty holders

Duty holders must assess delivery and collection risks and reduce them as far as reasonably practicable. Current arrangements for preventing vehicle accidents during deliveries and collections should be reviewed in consultation with safety representatives, drivers and employees. Consider what further steps you could take in cooperating to reduce risk.

General principles of good practice

The HSE advises safety arrangements for deliveries and collections should be assessed before orders are taken or placed. Planning safety precautions reduces the risk of accidents and can also save time and money. For instance, it should prevent deliveries being delayed or sent back because a site can't handle the load or the vehicle carrying it.

Incorporate safety arrangements in order-placing and order-taking documents so that the parties involved have to check that safety arrangements are adequate before authorising a particular delivery or collection.

The delivery vehicle driver plays a key part in delivery safety and is often the person injured in delivery or collection accidents - the driver should receive adequate safety information for each delivery or collection beforehand.

The agreement about delivery or collection safety arrangements can take different forms, for instance:

- Where a recipient regularly receives similar deliveries from a particular supplier or carrier all parties should agree a written delivery plan. If something about a particular delivery may make it unsafe to rely on the usual plan, the delivery should not start until the "special" precautions have been agreed by fax, email or telephone.

- When recipients, suppliers and carriers deal with each other on a "last-minute, one-off" basis it will usually be reasonably practicable to exchange basic delivery safety information and agree on the main precautions at the time an order is placed.

In some situations other parties may be involved. For instance, a recipient may place an order with a supplier who arranges for a third company to provide the goods, who in turn arranges for a haulier to make the delivery. Such complex arrangements can easily go wrong due to misunderstandings and failures in communication. The dangers of this should be considered before entering into these arrangements. If a delivery accident occurs, all parties in the chain may be asked to show that they took all reasonable steps to cooperate to achieve safety.

How suppliers, carriers and recipients can cooperate

All parties involved in deliveries should, so far as reasonably practicable, exchange and agree information to ensure goods can be delivered and collected safely.

In particular, the HSE says, consider:

- Any restrictions on the type or size of vehicle the site can safely handle.

- Any restrictions on when goods should be delivered or collected.

- Best approach routes to the site, especially if nearby one-way systems, low bridges, narrow roads, awkward access, etc. could cause problems for visiting vehicles.

- A site plan or sketch showing parking, location of reception, route to take through the site, location of (un)loading area, etc.

- Where visiting vehicles should park on arrival, where and whom to report to.

- The (un)loading area should be in a designated, adequately lit area from which people and vehicles not essential for (un)loading are excluded.

- Any procedures the visiting driver needs to follow, e.g. wearing high visibility vest, limits on use of mobile phones, prohibitions on reversing or conditions for reversing such as the use of a banksman.

- Who will be in overall charge of the (un)loading of visiting vehicles.

- What visiting drivers or site staff should do if they are not satisfied with safety arrangements for the delivery or collection (who to report concerns to, etc).

- Contact details for the other parties in case of problems.

- What to do if a load appears to have shifted dangerously in transit.

- The point at which the visiting driver will "give permission" for his vehicle to be un)loaded, and how this handover will be clearly understood by all.

- The method of (un)loading - what equipment is available, what is the capacity of the lifting equipment.

- Where the driver should be during the (un)loading of his vehicle. Drivers are often the victims of delivery accidents. A designated safe area for visiting drivers with easy, safe access to toilet and refreshment facilities reduces risks considerably. A safe area may be needed for drivers to observe loading.

- The delivery vehicle driver should not use a forklift truck (FLT) at a delivery site unless this has been agreed in advance and steps taken to ensure that the FLT is well maintained and the site suitable. The driver must also be trained to drive FLTs in accordance with the Approved Code of Practice.

- If access onto the vehicle is likely, how will falls be prevented or fall risks reduced.

- All parties should set up simple, well-understood systems for reporting any vehicle accidents, incidents, near-misses and other safety concerns during deliveries and collections, and exchanging information with the other parties. All should be encouraged to report incidents and concerns and appropriate action taken.

- Where deliveries or collections will take place regularly and special risks are likely, or at sites where visiting vehicles have had problems before it may be necessary for a manager to visit the site before sending further vehicles, to assess in more detail the risks involved and agree precautions.

- Are drivers able to understand English or does the plan need to be available in translation, use pictograms where possible.

Carriers - making collections and deliveries safely

Drivers may be faced with unexpected situations.

Carriers should train drivers in general safety precautions to take when visiting sites, in particular concerning the risks involved in (un)loading delivery vehicles, and give them clear instructions on what to do if they are not satisfied with the arrangements for ensuring safety at a particular site. Drivers should be authorised to refuse or halt the (un)loading of their vehicle on safety grounds.

In addition to training, providing drivers with simple delivery safety checklists may help them check that reasonable precautions have been taken, and help them decide if it is reasonable for them to refuse to continue with a particular delivery or collection.

Carriers should ensure that any agency drivers they use are familiar with the carrier's arrangements for delivery safety.

What the law requires

Employers have duties under the Health and Safety at Work etc Act 1974 to ensure so far as is reasonably practicable the health and safety at work of their employees and others who may be affected by their work activities (such as drivers). Under the Management of Health and Safety at Work Regulations 1999, where two or more employers share a workplace, even on a temporary basis, they must cooperate with each other to make sure they both comply with their legal duties.

These Regulations also require employers to carry out a risk assessment of the hazards involved and to identify measures needed to comply with health and safety legislation.

The Lifting Operations and Lifting Equipment Regulations 1998 require employers to ensure that all lifting operations are properly planned by a competent person, appropriately supervised and carried out in a safe manner. Lifting equipment needs to be suitable for the use to which it is being put, properly maintained, marked with its safe working load and periodically thoroughly examined and inspected.