Confined spaces: an obstacle for engineers

Earlier this year, Kettering General Hospital NHS Foundation Trust was fined £480,000 after an employee was found unconscious in a manhole. The man had been unblocking a drain at the hospital on 1 February 2022 when he was discovered by other members of staff.

He was rescued from the manhole by Northamptonshire Fire and Rescue Service and was treated at hospital for acute sulphate intoxication. This resulted in a traumatic brain injury, and ongoing issues with memory loss and nerve damage.

A Health and Safety Executive (HSE) investigation found that Kettering General Hospital NHS Foundation Trust failed to identify the manhole as a confined space, and thereafter, failed to properly risk assess the activity. The Trust failed to prevent entry of employees into confined spaces at the site – which was custom and practice for a number of years.

HSE inspector Heather Campbell said:

“This case highlights the dangers of working in confined spaces. The manhole should have been identified as a confined space, and risk assessed accordingly. Safe systems of work for entry into confined spaces should have been in place, such as those outlined in the HSE’s Approved Code of Practice.”

What the law says

Under domestic law (the Health and Safety at Work etc Act 1974) employers are responsible for ensuring the safety of their employees and others. This responsibility is reinforced by regulations.

The Confined Spaces Regulations 1997 apply where the assessment identifies risks of serious injury from work in confined spaces.

These regulations contain the following key duties:

- Avoid entry to confined spaces, e.g. by doing the work from the outside;If entry to a confined space is unavoidable, follow a safe system of work; and

- Put in place adequate emergency arrangements before the work start.

The Management of Health and Safety at Work Regulations 1999 require employers and self-employed people to carry out a suitable and sufficient assessment of the risks for all work activities for the purpose of deciding what measures are necessary for safety. For work in confined spaces this means identifying the hazards present, assessing the risks and determining what precautions to take.

Confined spaces in engineering

Confined spaces present significant safety challenges in various engineering activities, including construction, maintenance, and industrial processes.

A confined space is generally defined as an enclosed or partially enclosed space that is not designed for continuous human occupancy, has limited means of entry or exit, and may present hazards such as poor ventilation, limited oxygen supply, or the presence of toxic substances.

Confined spaces in engineering can include tanks, vessels, silos, tunnels, sewers, pipelines, and storage bins. These spaces can vary widely in size, shape, and environmental conditions but share the characteristic of restricted access. Engineers may encounter confined spaces in a wide range of tasks, including:

- Infrastructure inspection and maintenance: Engineers are often responsible for inspecting and maintaining infrastructure such as pipelines, sewers, tunnels, and storage tanks. These structures frequently contain confined spaces that require entry for inspection, repair, or maintenance activities.

- Construction and demolition: During construction projects, engineers may need to work in confined spaces to install or repair components, access underground utilities, or conduct welding or other construction activities. Similarly, during demolition projects, engineers may need to assess and address hazards within confined spaces before demolition can proceed safely.

- Industrial processes: In manufacturing and industrial facilities, engineers may need to access confined spaces within equipment, machinery, or process vessels for maintenance, cleaning, or troubleshooting purposes. These confined spaces may contain hazards such as moving parts, high temperatures, or toxic substances that require careful management.

- Utilities and infrastructure management: Engineers involved in utilities management, such as water treatment plants or electrical substations, may need to work in confined spaces to maintain or repair equipment, access underground infrastructure, or conduct inspections to ensure regulatory compliance and operational efficiency.

- Research and development: In research and development projects, engineers may work with prototype equipment or experimental setups that are housed within confined spaces such as chambers or enclosures. These confined spaces may be necessary to control environmental conditions or contain experimental hazards.

- Emergency response and rescue: Engineers may also be involved in emergency response and rescue operations, particularly in industries with high-risk confined-space environments such as mining, construction, or petrochemicals. Engineers may play a role in developing rescue plans, designing rescue equipment, or providing technical expertise during rescue operations.

- Environmental monitoring and sampling: In environmental engineering, engineers may need to access confined spaces such as underground storage tanks or monitoring wells to collect samples, install monitoring equipment, or assess environmental conditions for compliance monitoring or remediation purposes.

Overall, confined spaces are an integral part of many engineering activities across various industries. Engineers must have the knowledge, skills, and procedures in place to safely assess, enter, work in, and exit confined spaces to minimise risks to themselves and others.

The challenges for engineers

Confined spaces present significant challenges and risks in engineering for several reasons:

- Limited access and egress: Confined spaces typically have restricted entry and exit points, making it difficult for workers to enter and exit quickly in case of an emergency. This limited access can impede rescue efforts and increase the severity of injuries or fatalities if an incident occurs.

- Atmospheric hazards: Confined spaces often have poor ventilation, which can result in hazardous atmospheric conditions such as low oxygen levels, high concentrations of toxic gases or vapours, or the presence of flammable or explosive atmospheres. These atmospheric hazards pose immediate risks to workers' health and safety.

- Physical hazards: Confined spaces may contain physical hazards such as moving machinery, sharp objects, engulfment hazards (e.g. in grain silos or tanks), or unstable structures. These hazards increase the risk of injuries, entrapment, or even fatalities for workers entering or working within confined spaces.

- Difficulty in monitoring: Monitoring and assessing conditions inside confined spaces can be challenging due to limited access and visibility. Engineers may struggle to accurately assess atmospheric conditions, identify hazards, or monitor the activities of workers within confined spaces, increasing the potential for incidents to occur unnoticed.

- Potential for isolation: Workers entering confined spaces may become isolated from communication channels or assistance, particularly if communication systems fail or if the confined space is located in a remote or inaccessible area. Isolation can delay response times and exacerbate the consequences of emergencies.

- Complexity of rescue operations: Rescue operations in confined spaces are inherently complex and hazardous. Rescuing workers from confined spaces requires specialised training, equipment, and procedures to ensure the safety of both rescuers and victims. Limited access, atmospheric hazards, and physical obstacles further complicate rescue efforts.

The unique characteristics of confined spaces, including limited access, atmospheric hazards, physical obstacles, and complexity of rescue operations, make them a significant safety concern in engineering. Engineers must carefully assess and manage the risks associated with confined spaces to ensure the safety and wellbeing of workers involved in engineering activities.

Precautions

When working in confined spaces, engineers should take several precautions to protect themselves from hazards and ensure their safety. Here are some essential steps they should follow:

- Complete training: Engineers should receive comprehensive training on confined space entry procedures, hazards, emergency protocols, and the proper use of equipment. Training should cover topics such as atmospheric monitoring, ventilation, rescue techniques, and the use of personal protective equipment (PPE).

- Perform risk assessment: Before entering a confined space, engineers should conduct a thorough risk assessment to identify potential hazards and determine appropriate control measures. This assessment should consider atmospheric conditions, physical hazards, and any other factors that may pose risks to safety.

- Use atmospheric monitoring: Engineers should use atmospheric monitoring equipment to test the air quality inside the confined space before entry. This equipment can detect oxygen levels, flammable gases, toxic substances, and other hazards that may be present.

- Ensure proper ventilation: If necessary, engineers should implement ventilation systems to improve air quality and reduce the risk of atmospheric hazards within the confined space. Ventilation may involve the use of fans, blowers, or other equipment to supply fresh air and remove contaminants.

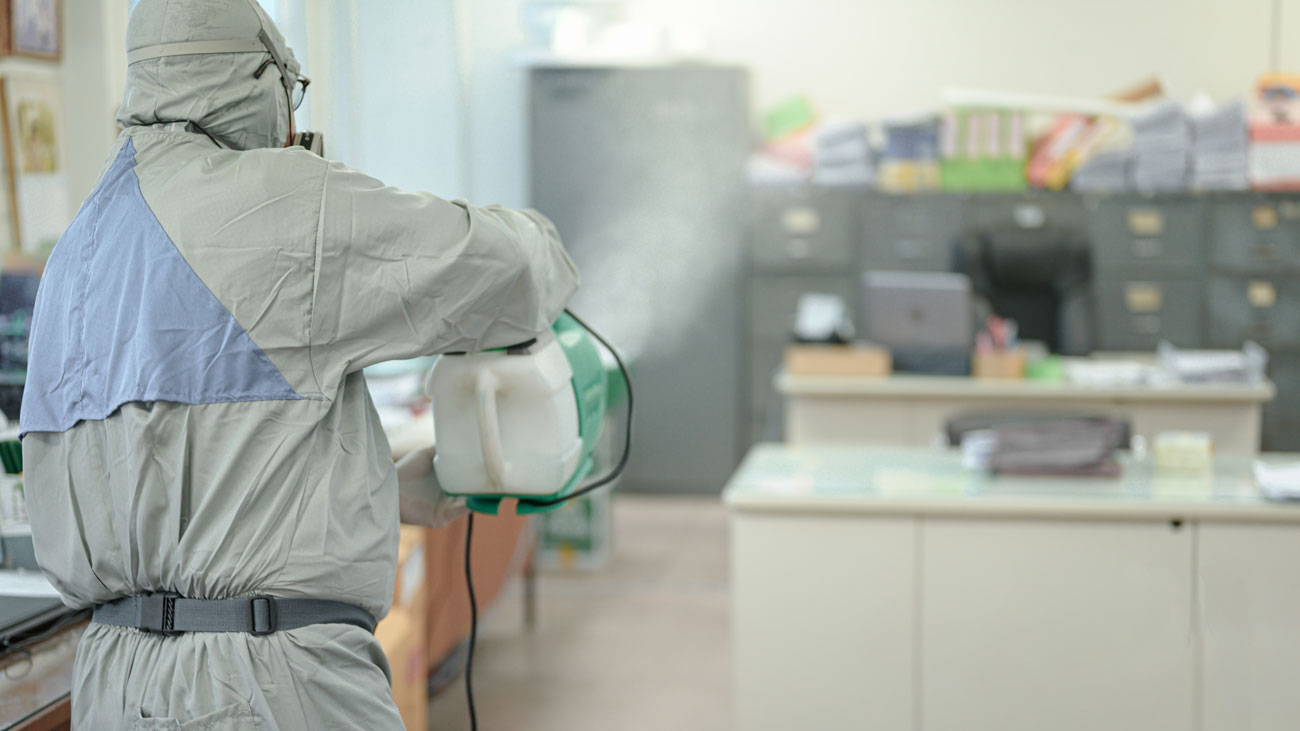

- Use Personal Protective Equipment (PPE): Engineers should wear appropriate PPE for confined space work, including respiratory protection, eye and face protection, protective clothing, and fall protection equipment as needed. PPE should be properly fitted, maintained, and used according to manufacturer guidelines.

- Implement entry control measures: Engineers should establish entry control procedures to manage access to confined spaces. This may include issuing entry permits, implementing lockout/tagout procedures, and posting warning signs or barriers to prevent unauthorised entry.

- Communicate and monitor: Engineers should maintain communication with colleagues outside the confined space using radios, hand signals, or other means. A designated attendant should monitor the activities of workers inside the confined space and be prepared to initiate emergency response procedures if necessary.

- Follow safe work practices: Engineers should adhere to established safe work practices and procedures for confined space entry, work, and exit. This includes following established entry and exit procedures, avoiding unnecessary risks, and promptly reporting any concerns or incidents to supervisors.

- Develop emergency response plans: Engineers should develop and familiarise themselves with emergency response plans for confined spaces, including procedures for rescue and evacuation. This may involve coordinating with emergency responders, maintaining rescue equipment, and conducting regular drills and simulations.

- Continuous training and review: Engineers should participate in regular training and review sessions to refresh their knowledge of confined space safety practices, stay informed about updates to regulations or procedures, and reinforce best practices for working safely in confined spaces.

By following these precautions and procedures, engineers can help ensure their safety when working in confined spaces and minimise the risks associated with these challenging environments.

HSE guidance on confined spaces can be found at Introduction to working in confined spaces.

International Workplace's IOSH Managing Safely course features a module on workplace hazards, including confined spaces and hazardous substances. Learners will understand the different categories of hazards that can occur in a workplace and ways to control and manage these hazards. Find out more here.